Утилита Devid. info ™ использует технологию сбора данных для удобного обновления драйверов для вашего ПК. Драйверы являются собственностью и ответственностью соответствующих производителей, а также могут быть бесплатно доступны непосредственно на сайтах производителей. Devid. info не несет никакой ответственности за производительность или проблемы, вызванные драйверами сторонних производителей. Драйверы также могут быть доступны бесплатно непосредственно с веб-сайтов производителей. Microsoft и Windows являются зарегистрированными товарными знаками или товарными знаками корпорации Microsoft в США и/или других странах. Любые другие продукты, торговые марки или товарные знаки сторонних производителей, перечисленные выше, являются исключительной собственностью их соответствующих владельцев. Devid. info никак не аффилирован с этими компаниями.

Simultaneously AMS fall in the class of organizational, hierarchical, multifunction, multiple objective, multiply connected nonlinear dynamic complex systems which consist of subsystems set of different physical nature (structural subdivisions), agents, having own local purposes and containing the man as active element.

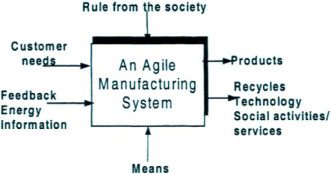

From: Agile Manufacturing: The 21st Century Competitive Strategy, 2001

- 3 Agile manufacturing system

- 2 Functional view of agile manufacturing systems

- 1 Agile design

- 2 Agile planning

- 3 Agile production

- AGILE MANUFACTURING SYSTEMS AS COMPLEX DYNAMIC CONTROLLED OBJECT

- Summary.

- Special cases of q=0 and r=l

- 4 Agile Manufacturing System

- REMARKS

- CONCLUSIONS

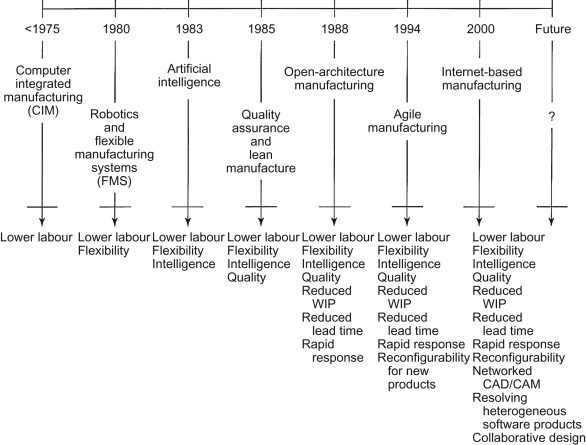

- 1 Overview of the Manufacturing Evolution

3 Agile manufacturing system

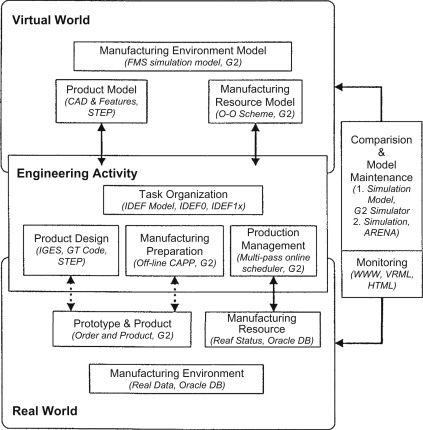

AM systems (AMSs) are characterized by a high level of dynamism, and nonequilibrium functioning regimes are dominating this class of systems. Simultaneously, AMSs fall in the class of organizational, hierarchical, multifunction, multiple objectives; multiply connected nonlinear dynamic complex systems that consist of subsystems set of different physical nature (structural subdivisions), agents, having own local purposes and containing the man as an active element (Ilyasov, Ismagilova, & Valeeva, 2001). Due to the inherent complexities and agility associated with the modern manufacturing systems, modeling these complex interacting subsystems using common analytical and mathematical approaches has proved to be very difficult (Wang, 2001).

Agility is a quality of timely response to changing conditions. For an organization, it is quickly and successfully adapting to change which may be in any area such as market, regulation, or technological advancement (Vernadat, 2001).

In the year 1991 the Iacocca Institute (in its vision document titled 21st Century Manufacturing Enterprise Strategy primarily created for the US industry) highlighted the need for an agile enterprise, which could operate efficiently and effectively in a rapid and unpredictable change environment. Such business environments are constantly changing and highly competitive (Bruce et al. , 2004). The ultimate objective of the vision document was to encourage a transition from mass production to AM in pursuit of regaining the manufacturing leadership by the US industry (Küçük & Güner, 2014; Nagel & Dove, 1991).

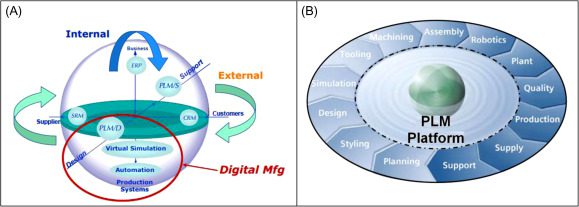

In his book, Agile Manufacturing: The 21st Century Competitive Strategy, Gunasekaran (2001) describes AM as the capability of surviving and prospering in a competitive environment of continuous and unpredictable change by reacting quickly and effectively to changing markets, driven by customer-designed products and services. Critical to accomplishing AM are a few enabling technologies such as the standard for the exchange of products, concurrent engineering, virtual manufacturing, component-based hierarchical shop floor control system, and information and communication infrastructure (Gunasekaran, 2001).

According to Christopher and Towill (2001), “Agility is a business-wide capability that embraces organizational structures, information systems, logistics processes and in particular, mindsets. ” Being flexible is a key characteristic of an agile enterprise. Hence, the roots of agility lie in the concept of flexible manufacturing systems (Christopher & Towill, 2001).

Initially, the manufacturing flexibility was limited in scope, and the key focus was on automation and rapid changeovers only enabling the manufacturing of orders with product mix or volume. In later years the concept of agility (flexibility) was extended to a larger business context (Nagel & Dove, 1991).

Read full chapter

2 Functional view of agile manufacturing systems

Agile manufacturing systems can be conceptually thought of as being an integrated whole of complex interacting sub-systems, organized in such a way as to endeavor towards a common set of goals (Merchant, 1984). Due to the inherent complexities and agility associated with the modern manufacturing systems, modeling these complex interacting subsystems using common analytical and mathematical approaches has proved to be very difficult.

Figure 2. A functional scheme of an agile manufacturing system

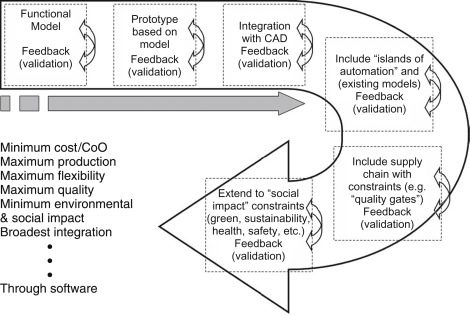

Functional view of agile manufacturing systems (shown in Figure 2) and all the issues related to these sub-systems have been combined into three major issues: agile design, agile planning, and agile production.

1 Agile design

In agile manufacturing systems, according to the dynamic customer requests, along with the feed-back from the system and/or surroundings, the product conceptual design is carried out and normally there is a great need for product innovation. Subsequently, the product is configured and parameterized. Product manufacturability is considered and tested using simulation tools. The corrections are made iteratively and finally the product is manufactured. CI approaches have been implemented for conceptual, configuration, and parametric design activities.

2 Agile planning

Process Planning, scheduling and manufacturing resource planning (MRP) are considered as three major items in the planning sub-system. Process planning transforms information of a product into sequences of operations with a schedule. Scheduling and MRP are carried out as service functions. CI techniques appear to be the perfect approach in dynamic planning, scheduling and manufacturing resource planning.

3 Agile production

In most advanced agile manufacturing environments, completely and semi-autonomous systems are used. In order to ensure that the agile manufacturing process is under good control, it is necessary to monitor the process, obtain process and product information, diagnose the problems, and control the process. The main functionality in production is process modeling, monitoring, diagnosis, control, inspection and assembly. ANN and FLS techniques are frequently applied to the production functionality for improving the learning ability and adaptability of systems.

AGILE MANUFACTURING SYSTEMS AS COMPLEX DYNAMIC CONTROLLED OBJECT

Recently agile manufacturing systems gain wide acceptance among modern classes of manufacturing systems (MS). This class presents further development of flexible manufacturing systems. It is characterized by not only more high level of integration, but also more high level of intellectualization and self-organization, and also capacity to adapt quickly and effectively to unpredictable changes of an environment. In these systems organizational knowledge and experience, human factor and modern advanced technologies are combined optimally.

to adaptation (structural and parametric, by means of restructuring production among them);

to development, by means of forming of optimal strategic schedules;

to fast change of the current productive schedules according to changes of both market situation, and interior state of manufacturing system;

to fast reorientation to change of product mix;

to fast change of behavior tactics in competitive market conditions;

to making of intelligent control decisions in uncertainty conditions;

to creation of temporary organizational structures which ensure faster effective reaching of the finite purpose.

development of adequate models of a system both in equilibrium, and in non-equilibrium functioning regimes;

authentic and complete enough change description of an interior system state and an environment state in various situations which are generated by action of random and uncertain factors;

forming of such control actions on AMS in uncertainty conditions which would ensure either functioning effectiveness of a system, or achievement of the local and global purposes, or preservation of stability at presence of failures, loss of information and other factors which lead to origin of unnominal (critical, emergency, crisis) situations;

development of efficient algorithms for rebuilding of organizational structure of agile manufacturing system according to change of production and market situations;

co-ordination of the local purposes of subsystems and global purpose;

taking account human factor which introduces subjective and uncertain character in the functioning process of agile manufacturing system.

choice of the global and local purposes and their concordance functioning effectiveness criterions of a system;

timely deriving of the authentic information about a current state of object and environment;

exposure of state variables, controlled output coordinates and control factors (actions) which ensure purposeful motion of a system;

synthesis of decision making algorithms for forming control actions: their form, magnitude, sign, and also time and point of application;

security of timely and qualitative fulfillment of made decisions.

Summary.

Agile manufacturing system represents complex dynamic controlled object, badly-formalizable, with unpredictable behavior, especially in uncertainty conditions. Therefore, to control such object it is necessary to apply intelligent algorithms realized by means of modern information technologies.

Special cases of q=0 and r=l

Special case of q=0 represents the decision situation of a given AMS in which there is no interaction between its elements. For this case the analytical model reduces to zero the value of any piece of information resulting from communication (AMS element seeks only this information that describes its own part of the external environment). For q=0 there is no interaction in the internal environment and the actions of the elements of AMS are independent. For such a case information exchange inside AMS does not affect the value of the information structure. For example, although information structure C4 contains a larger amount of information than C2, their VC values are the same for q=0. Thus we have:

Special case of r=l represents the decision situation in which the relationship between the variables describing the external environment is of functional character (not statistical). It is similar to the case of q=0 as the value of any piece of information resulting from communication is reduced to zero. Thus we have:

the computation involved in information flow analysis and evaluation may become complex and prohibitive,

complete and certain information that the analytical models require is often not available.

Simplified modelling approaches are needed that can be used to describe and understand the flow of information in AMS. Such approaches are presented next.

4 Agile Manufacturing System

Agile refers to an uncertain and complex environment with unanticipated demand patterns. This is synonymous with volatility and turmoil. Agile manufacturing systems are dynamic in responding to customer needs with faster learning and quick decision making. Such an agile system-based organization is designed for both stability and dynamism and it operates as a network of teams. Such systems are best suited for volatile, uncertain, complex, and ambiguous (collectively termed as VUCA) environments. Sometimes, these systems are also treated as the next (or advanced) version of lean manufacturing systems.

Agile manufacturing systems are also synonymous to such quick response manufacturing systems, which are referred to as the manufacturing systems aiming to fulfill the customer demand with a shorter lead time to fulfill the customer demands in a shorter time, such systems are designed to handle low volume high variation products.

Also see: WCM (World Class Manufacturing)

REMARKS

IT has a key role to play in achieving manufacturing agility and can affect all the major functions of a manufacturing system. On balance, IT facilitates the operation of an agile manufacturing system and in the main acts as an enabler. However, the support of senior management is necessary for the achievement of manufacturing agility. It has been shown that the introduction of a new IT intervention may generate uncertainty within the workforce and the support of senior management is vital in maintaining the manufacturing process. On some occasions, the introduction of IT has created problems with the workforce and other members of staff(Wilson, 1994), so top management must be cautious in this task. If IT increases management control by top management, this needs to be applied without creating undue stress and concerns.

CONCLUSIONS

In case of small batch productions with dynamic changes in volumes and varieties of products, the conventional manufacturing systems are not adaptable, and thus, new architectures of manufacturing system have been proposed. The new architectures known as autonomous distributed manufacturing systems cope not only with the dynamic changes but also with the unscheduled disruptions such as the breakdown of equipment and the interruption of high priority jobs. Holonic manufacturing system is one of the autonomous distributed manufacturing systems besides biological manufacturing systems, fractal manufacturing systems and agile manufacturing systems. (1)-(4)

The objective of the present research is to develop an integrated process planning and scheduling system applicable to the holonic manufacturing system. In the previous papers(5)-(6), integration of process planning and scheduling was carried out, wherein the scheduling system for multi-products as a whole uses the process plan information of a set of individual products to generate a suitable schedule. But, there is not any feedback information from the scheduling system to the process planning system. This paper deals with the integration of the process planning and the scheduling systems where there is a scheduler driven modification of the process plans of the products. A systematic method is proposed to generate modified sequences of machining equipment for the individual products based on the feedback information of the scheduling results, and to generate a modified production schedule for the whole manufacturing system.

In this chapter, we have looked at recent developments in the area of manufacturing systems control that are focused on the goal of achieving rapid, adaptive response to change in the manufacturing environment. A primary concern of recent research in this area has been the choice of architecture, or in other words, how the decision-making agents in a control system should be organised to effectively achieve overall manufacturing system objectives.

If these partial hierarchies are to be adaptable and reconfigurable, the control system will also have to be capable of responding to changes in the manufacturing environment. In other words, partial “dynamic” hierarchies will result that should not only be thought of as hybrids of heterarchical and hierarchical control architectures, but should also be thought of as metamorphic control systems. That is, these systems will adapt their architecture to respond to changes in the manufacturing environment.

1 Overview of the Manufacturing Evolution

На основании Вашего запроса эти примеры могут содержать грубую лексику.

На основании Вашего запроса эти примеры могут содержать разговорную лексику.

A system manufacturer is able to carry-out this work on the basis that a wide range of vehicles are available during the validation and application engineering phases and by anticipating future demand for the system. Изготовитель системы в состоянии проделать эту работу при наличии широкого диапазона транспортных средств на этапах апробирования и разработки применения с прогнозированием будущего спроса на соответствующую систему.

SME’s are, therefore, discriminated against unless a system manufacturer is able to carry-out this work. Поэтому если изготовитель системы не в состоянии проделать эту работу, то речь идет о дискриминации МСП.

As a system manufacturer, Vaillant offers its partners optimally matched components from a single source — for fast and efficient installation of individual heating, ventilation and cooling solutions. Как производитель систем, Vaillant предлагает своим партнерам оптимально согласованные компоненты из одних рук — для быстрого и эффективного монтажа индивидуальных систем отопления, вентиляции и охлаждения.

our company is a system manufacturer and integrator.

Для обеспечения возможности использования изготовителем механического транспортного средства процедуры, предусмотренной в части 2 приложения 19, независимо от того, является ли этот изготовитель транспортного средства также изготовителем системы, и для уточнения данного обстоятельства предлагаются следующие поправки:

Ничего не найдено для этого значения.

Результатов: 5. Точных совпадений: 5. Затраченное время: 1079 мс

Documents

Корпоративные решения

Спряжение

Синонимы

Корректор

Справка и о нас

Индекс слова: 1-300, 301-600, 601-900

Индекс выражения: 1-400, 401-800, 801-1200

Индекс фразы: 1-400, 401-800, 801-1200